New textile fibers deliver drugs to targeted areas with greater efficacy

Several initiatives are thus underway seeking to advance drug delivery methods

(Web Desk) - Empa researchers have developed textiles that deliver drugs to targeted areas with greater efficacy than conventional methods.

Currently, drug delivery routes include injection, parenteral, oral, sublingual, inhalation, suppository, implant, or topical pathways.

However, local delivery remains ideal as it evades the need for the drug to travel through the bloodstream which accounts for high dosages.

It’s to ensure that some of the therapeutics reach the desired destination often with unwanted side effects, however, because of these high levels.

Several initiatives are thus underway seeking to advance drug delivery methods as they aren’t as direct or as sensical as they could be.

So forget syringes, needles, and even pills, perhaps, as textiles offer “greater efficiency and convenience,” according to a group of Swiss scientists at Empa.

As stated in their recent study, “textiles for drug delivery” stands to revolutionize local drug delivery methods in the rapidly growing field of personalized medicine.

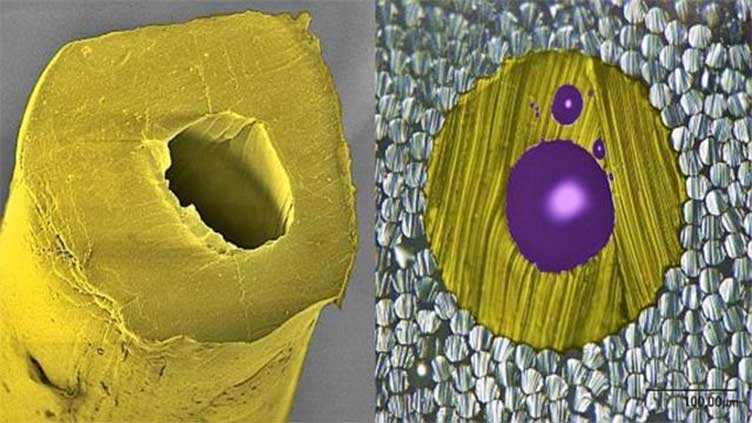

And Empa’s melt-spun liquid-core filaments (LiCoFs) have advanced this new arena due to how they manufacture them.

Coating thin threads of fabric with medicine

Textiles have a long history in medicine: wound dressings, synthetic graft substitutes, scaffolds for tissue repair and regenerations, and even face masks.

Loaded with drugs, these fibers use “physical and chemical processes such as absorption, coating, encapsulation, grafting or covalent conjugation, particularly for transdermal applications.”

The field however has yet to develop “smart textiles, stimuli-responsive textiles capable of releasing drugs on demand, triggered by external factors such as ultrasound, pH, temperature or electrical fields.”

The liquid-core filaments (LiCoFs) developed by Empa achieve this goal due to a process called “melt spinning.” It enables several functionalities to exist in one fiber, as per their website.

“We firmly believe that these innovative melt-spun LiCoFs represent a significant advancement in the realm of medical textiles.”

Is future of face masks upon us?

“To the best of our knowledge, this article reports for the first time a direct drug incorporation using a liquid-core melt-spinning technique,” they stated.

Unlike other techniques such as electrospinning and force-spinning, melt-spinning offers many advantages. It’s cost-effective, industrially viable, and offers that smart capabilities that the field needs.

Adjusting the textile changes the rate at which the drug is released, New Atlas pointed out. And the fiber biodegrades in the body.