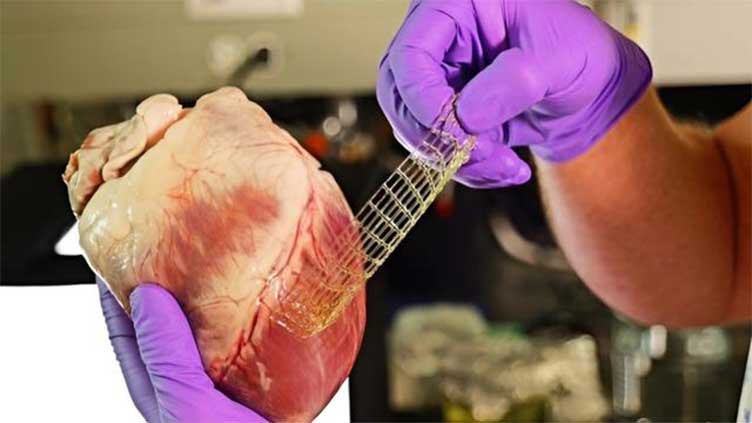

New 3D-printed flexible patch to repair damaged tissues

A new form of material that functions like bandages has the potential to repair damaged hearts

(Web Desk) - Researchers have created a new method for 3D printing materials that mimic the strength and flexibility of human tissue.

The University of Colorado Boulder partnered with the University of Pennsylvania to develop this new 3D print method called Continuous-curing after Light Exposure Aided by Redox initiation (CLEAR).

Interestingly, this approach will yield materials with a unique combination of properties: flexibility to endure the heart’s constant beating, toughness to resist joint pressure, and adaptability to fit specific patient requirements.

The team hopes this technique will give rise to advanced biomaterials such as drug-infused heart bandages, cartilage patches, and needleless sutures.

“Cardiac and cartilage tissues are similar in that they have very limited capacity to repair themselves. When they’re damaged, there is no turning back. By developing new, more resilient materials to enhance that repair process, we can have a big impact on patients,” said Jason Burdick, senior author.

3D printers build objects layer by layer using various materials, including living cells. Hydrogels are popular for making artificial tissues, however standard 3D-printed hydrogels sometimes lack the strength and flexibility required for medical applications.

“Imagine if you had a rigid plastic adhered to your heart. It wouldn’t deform as your heart beats. It would just fracture,” said Burdick.

However, this new 3D process produces robust, flexible materials that may stick to moist tissue. CLEAR works by intertwining long molecules in 3D-printed materials. This idea came from intricate entanglement found in worms.

The newly-created materials were subjected to rigorous stretching and weight-bearing testing, including a rather unusual procedure in which a bicycle moved over the sample.

They found that the materials were incredibly tougher than those created using the standard 3D printing process. Impressively, these materials also demonstrated compatibility and adhesion to animal tissues and organs.

“We can now 3D print adhesive materials that are strong enough to mechanically support tissue. We have never been able to do that before,” said Matt Davidson, co-first author and a research associate in the Burdick Lab.

Burdick and team envision a future where these 3D-printed materials could be employed to mend cardiac defects, administer tissue-healing drugs directly to organs, stabilize herniated discs, and perform sutureless surgical closure.

Moreover, this approach is environmentally friendly as it bypasses the energy-intensive hardening phase typically required in 3D printing.

“This is a simple 3D processing method that people could ultimately use in their own academic labs as well as in industry to improve the mechanical properties of materials for a wide variety of applications,” said Abhishek Dhand, first author and a researcher in the Burdick Lab, in the press release.

The team has filed a preliminary patent and will soon conduct further research to examine tissue response to these materials.

The findings were reported in the journal Science.